Wire bending Machine News

The latest informative articles, helpful guides, and industry insights to enhance your understanding of wire bending manufacturing.

In order to better explore overseas markets and serve global customers, the foreign trade team of Belan Machinery has embarked on a new round of skill enhancement journey! Today, they walked into the workshop and started learning how to debug the machine, gaining a deep understanding of the construction principles, performance characteristics, and operational skills of the bending machine.

The first lesson of construction in 2025, the Braun wire bending machine sounded the horn of charge! With an annual growth target of 28.3%, everyone has their own indicators, betting agreements stimulate potential, technological innovation drives development, and we strive to build a leading brand in China's wire forming industry by doing fine and precise work to solidify our foundation!

Recently, our company successfully completed the production of a 14mm CNC wire forming machine and delivered it to our Polish customers. This marks another significant achievement for us in the international market and once again proves our company's leading technology and excellent quality in the field of CNC equipment.

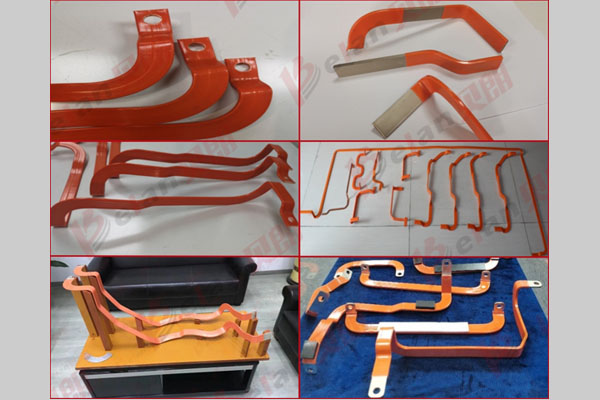

The technical characteristics of the multifunctional combination wire bending machine are mainly reflected in its high flexibility, precise processing capability, advanced control system, and efficient production efficiency. The following are the specific technical characteristics of the multifunctional combination bending machine:

It can be bent flat, vertically or twisted, and short straight lines can be formed by hedging, which is suitable for the forming of copper and aluminum bars. Servo Control Precision Guarantee

Nowadays, many metal product forming companies are using 2D and 3D steel wire bending machines. However, after product upgrading in recent years, 3D steel wire bending machines have much better characteristics, more precision and faster speed. Many people have asked, as the current popular equipment, what is the structure of the steel wire bending machine?

What are the advantages of automatic wire forming machine

Wire forming machine is a large-scale industrial equipment, so it needs regular maintenance to ensure the normal operation of the machine, which helps to increase the service life of the machine.

Spring machine: can process wire diameter range of 0.3mm-10.0mm, and can process simple and complex wire shaped products.

wire forming machine

A compound bend is "a feature in a line form that has two adjacent bends or builds without a straight length tangent to the start and end points of these radii." In simpler terms, compound bend involves making two The bends are so close to each other that there is no perfectly straight wire between them

Mechanical maintenance is a common topic, and proper maintenance also needs to be learned. Today we will show you the special maintenance of 3D steel wire bending equipment.

Today, I will introduce the process of 3d wire forming machineto produce iron wire bending products?

The acceptance criteria for wire bending equipment mainly include the following points:

It is the key to ensure the accuracy, speed and stability of the CNC wire bending machine during operation. What are the main factors to ensure the stability of the CNC wire bending machine?