Wire bending Machine News

The latest informative articles, helpful guides, and industry insights to enhance your understanding of wire bending manufacturing.

The international working women's day

When it comes to the debugging of wire bending equipment, both technical engineers and apprentices need to master their debugging skills, otherwise they will not debug a perfect product.So, what skills do beginners need to master when learning this type of machine?

Technical personnel in the debug bending machine, large and small will encounter strange questions, sometimes because of wire rod quality problem, cutting tool size problem, personnel, technology, and so on all can bring certain influence to the precision of, but in addition to the above these reasons, but there is another reason why is ignored by the people, that is temperature can also lead to the precision of steel wire forming machine,

A product how to let the user like or praise depends on its beauty, quality, use to decide, including wire molding machine here is the same truth, in fact, customer reputation is not our own blow out, but users pass ten, ten spread hundreds of, you say?

Everyone's talent is different, the degree of acceptance is not the same, the master time is not the same, today share how to quickly master the debugging of wire bending machine

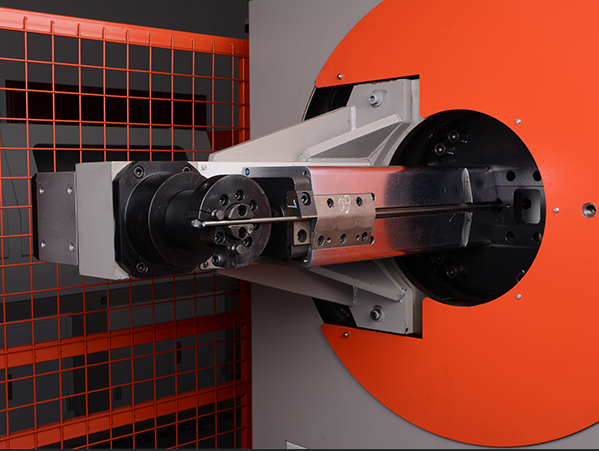

In view of the current market environment, the accurate choice of 3D bending machine has become a difficult enterprise, why say so?Because now this type of manufacturers like bamboo shoots after a spring rain, the quality of each manufacturer of machine is uneven, as demanders, we should how to accurately choose 3D bending machine?

When adjusting the speed of wire frame, there will be a wire frame speed switch for adjustment, and there is an automatic speed, automatic speed is in the process of your production wire frame will automatically rotate according to the speed of your production, when the machine stops when the wire frame will automatically stop

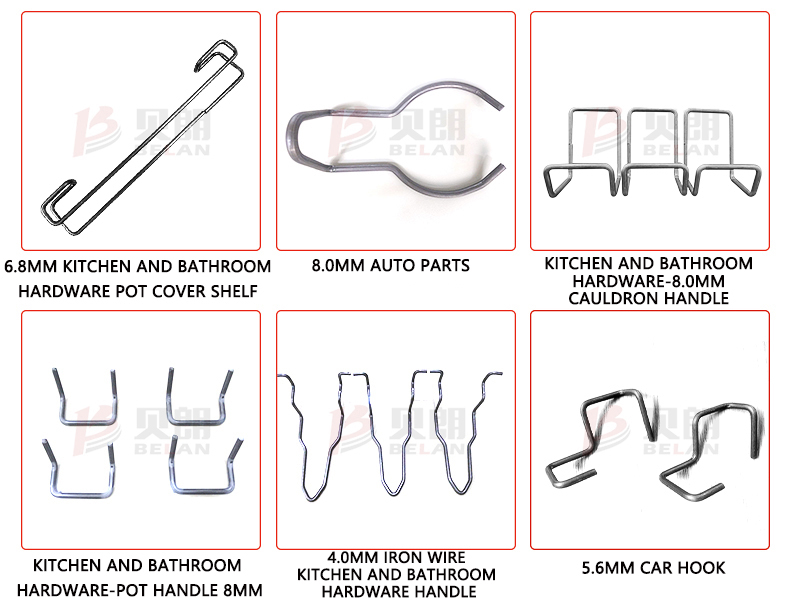

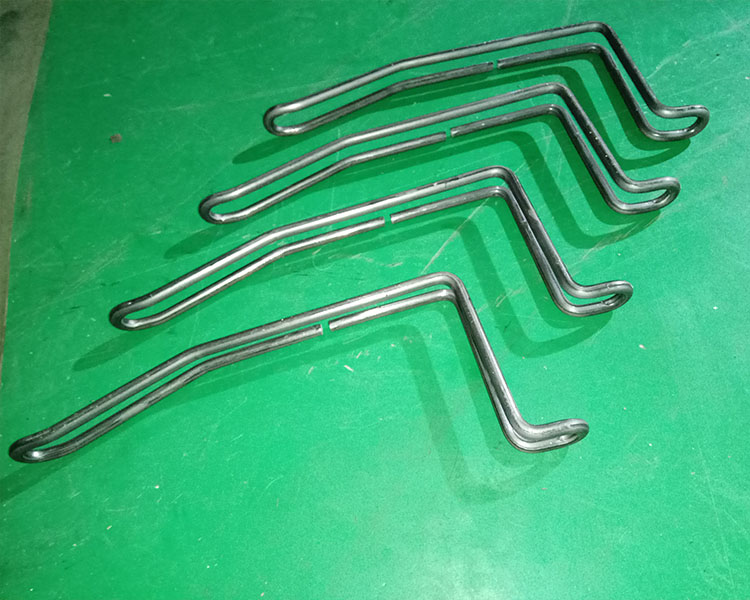

Before we choose an ideal wire bending machine, we want to use proofing to test the stability and accuracy of the bending machine. Prior to the cooperation, Braun provided samples to customers for a certain fee.

If the bending machine servo alarm solution is very simple, start the equipment again.What causes this?

Wire bending machine in the long run, it will inevitably appear small problems, such as the following problems, how should we solve it? A piece of wire bending machine circuit connection head loose, resulting in loose

Fan net cover I believe many people have seen, do you know what kind of metal wire forming machine it is produced?Let's get to know this model!

Use wire bending device, in addition to we have a professional technical steps, and a detailed set of lines forming production process, look, although only two aspects but need to pay attention to in the process of its operating items or more, otherwise, sometimes by accident because of a mistake to large damage to the machine, so technical personnel in the operation of the iron wire bending equipment,What should be paid attention to?To solve this problem, do a simple share, hope you find it useful.

We provide a 1-year free warranty and lifetime free training service

Are you a trading company or manufacture?

In the middle of April, through the cooperation of Belan production department personnel, the bending machine purchased by Suzhou customers successfully arrived at the customers after packaging, logistics and transportation. Next, follow Beilang's steps to the customers' site to have a look!