Product Description

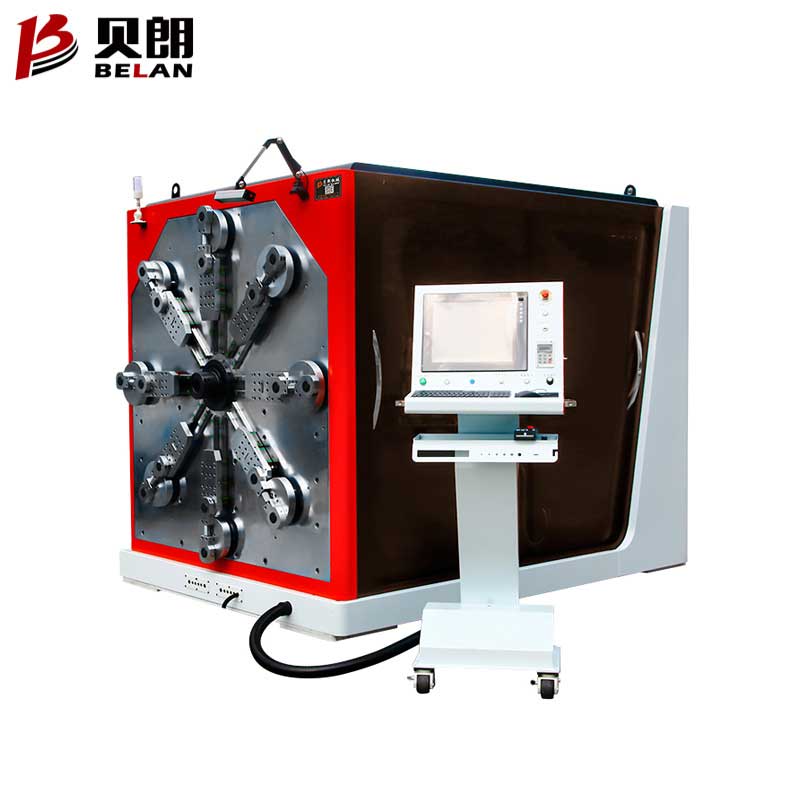

1. The feeding mechanism adopts a crawler structure, which can better fit the surface of the copper and aluminum bar insulation layer to increase adhesion and promote wire feeding to ensure wire feeding accuracy. There is no need to change the feeding wheel to switch to different wire diameters, just adjust the stroke.

2. The marking equipment can realize flat bending, vertical bending, twisting bending, punching, chamfering, heating functions, double curling forming, and can achieve different R angle bending.

3. The equipment comes with an auxiliary feeding mechanism, and a single person can complete the installation and commissioning of 300² materials.

4. The equipment system is simple to operate. Through manual programming, the product shape can be quickly adjusted to shorten the mold trial cycle.

5. The straightening structure has a scale, which can memorize the scale data to facilitate the replacement of different specifications for straightening, which is convenient and simple.

6. Support docking with customer MES, support cloud sharing of process data, and 100% production data traceability.

7. The wire feeding has a compensation function. The wire feeding accuracy is 300mm±0.1; the angle accuracy is 90°±0.2.

Technical Parameters

| Type | BL-TP-30-5E Parameter |

| Applicable Wire Dia. | width Φ:2.0-5.0mm thickness Φ:5.0-30mm |

| Number of control Axis | 12 Axis |

| Total power | 25.7KW |

| Crawler feeding | 1PC |

| Power of wire feeding motor | 4.5KW |

| Power Of wire turning Motor | 2.7KW |

| Servo shear motor motor | 1.0KW |

| Power Of Arm Motor | 2.0KW*8 |

| Power Of Curl Motor | 1.5KW |

| Angle accuracy | 90°±0.2° |

| Input Power | 380V/50Hz/3Ph |

| Weight | 3800KG |

| Maximum load weight of automatic wire feeder: | 1000KG |

| Machine Size(L*W*H) | 2800*2100*2000mm |

| Site occupation: | length 6800mm * width 2500mm |

Product Advantages

It can be bent flat, vertically or twisted, and short straight lines can be formed by hedging, which is suitable for the forming of copper and aluminum bars.

Servo Control Precision Guarantee

It adopts servo imported from Japan and is controlled by professional CNC computer to ensure high-precision wire feeding, high-precision bending, and high-quality cutting.

Caterpillar feeding reduces mold

Using crawler-type wire feeding structure to reduce scratches on copper strips, and no need to change molds for different sizes, improving efficiency

Wire Bender Videos

Product Application

Products Are mainly Used In Automobiles, Kitchenware, Garden Tools, Supermarket Shelves, Furniture, etc.

Wire Forming Drawing

Manufacturing Capacity

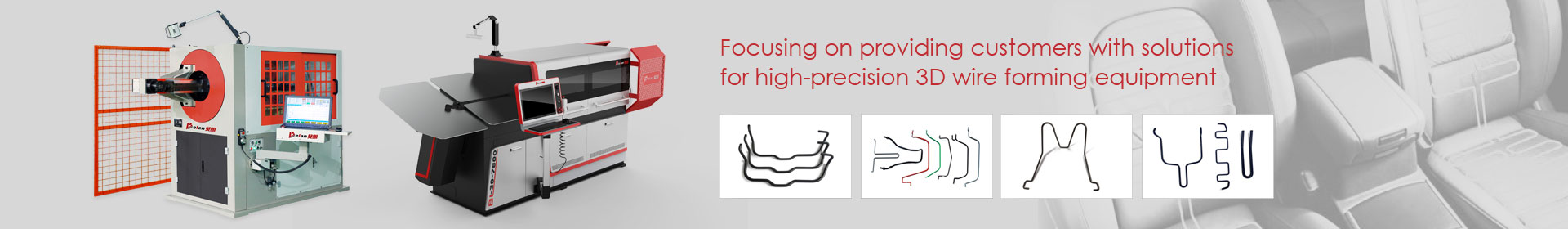

Belang automation equipment co., LTD. is an innovative technology enterprise integrating r&d, manufacturing, sales and system integration services. Focusing on providing customers with solutions for high-precision 3D wire forming equipment, we are committed to promoting the transformation and upgrading of China's manufacturing industry to intelligent manufacturing.

Honor Certification

Customer case

+86-18098256570

+86-18098256570  Email

Email