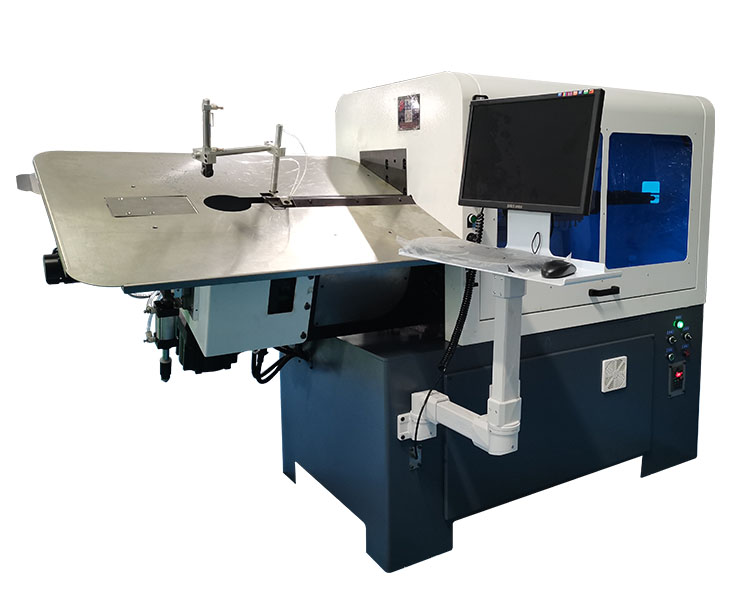

Briefly introduce the working principle of the machine:

The first step is to place the coil material on the automatic wire feeding rack, and the servo motor pulls it to the straightening mechanism

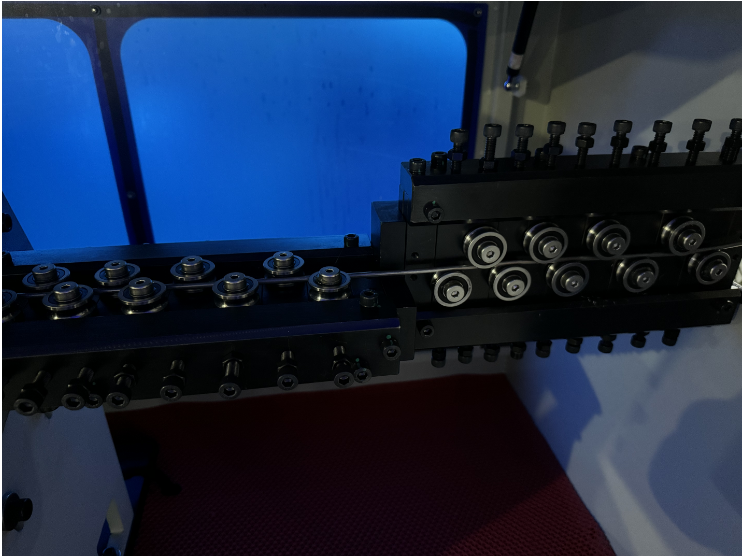

Secondly, adjust the tightness of the two sets of upper and lower screws to straighten the wire and bring it to the wire feeding wheel;

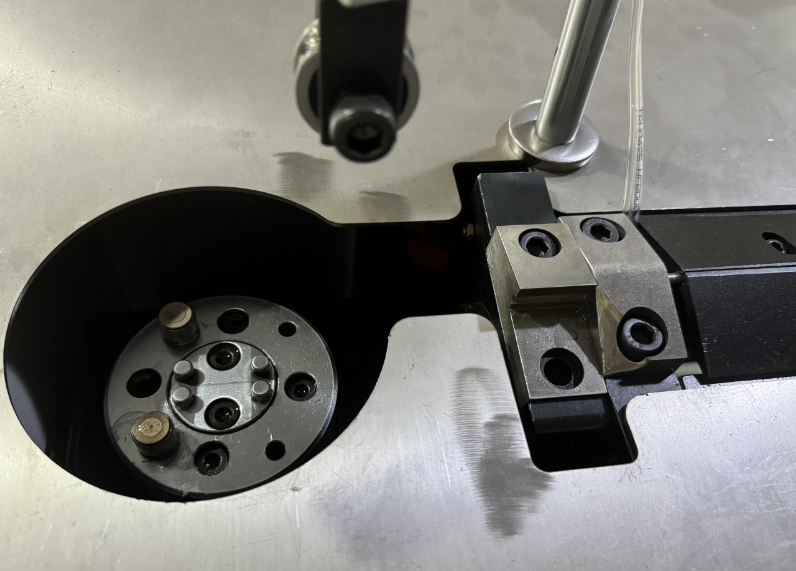

The third and third sets of wire feeding wheels deliver the wire to the bending area;

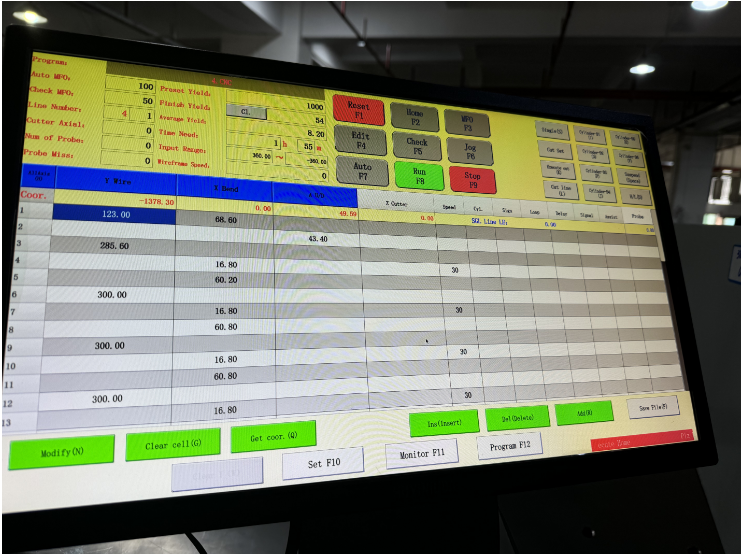

Fourthly, edit the data program on the system, bend and cut, and click on automatic production;

Fifth, complete all steps

If you would like to learn more about our models, please contact us and we will provide you with high-quality pre-sales and after-sales service

+86-18098256570

+86-18098256570  Email

Email