The overall configuration and structure of the wire bending machine with different structures are different. Today, I'd like to talk about some structures of the wire bending machine with Belan turning head. The machine has the following structure:

1. Wire feeding rack: mainly used for automatic wire feeding when the facility is in operation;

2. Transformer: when a higher voltage is transmitted to the facility, the transformer has the function of regulating current;

3. Material transfer installation: with the role of conductor and small fluctuation wire;

4. Straightening frame: the straightening frame is mainly used as straightening material in the facility. The straightening frame has 3.6mm and 6.8mm discrimination. When consuming products, the straightening frame shall be stopped according to the size of wire rod;

5. Wire feeding wheel: the facility has the performance of wire rod guarantee during operation;

6. Motor: it can control the operation of the machine;

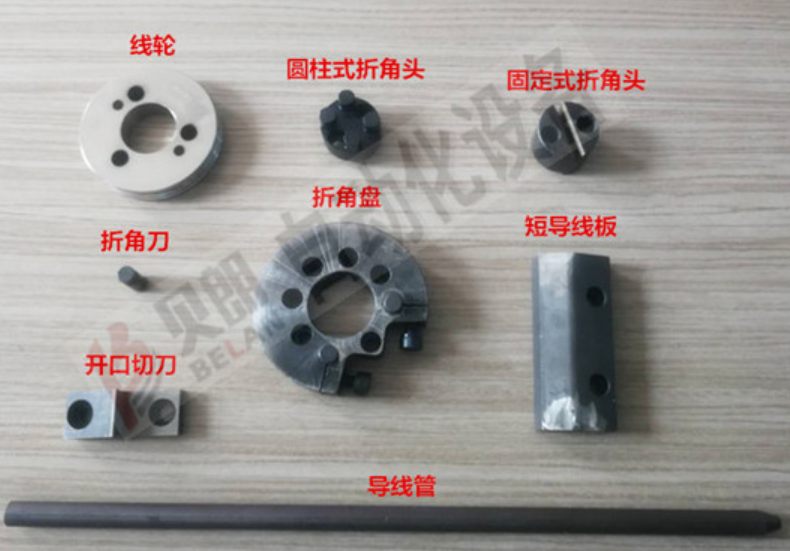

7. The related cutting tools of wire forming machine, such as wire feeding wheel, wire pipe, short wire board, open-end cutter, closed-end cutter, cylindrical angle bending head, fixed angle bending head, angle bending disk and small straight angle bending cutter, all play corresponding roles in stopping the bending and forming of products;

8. Task light: the function of illuminating a certain part of the machine when the facility is running;

9. Hand wheel: it can be manually operated and controlled when debugging products;

10. Operation platform: if the machine operation platform is keyboard and display, operate the machine during commissioning;

11. Tool car: some accessories of the facilities, such as gongs, wire knives, plate hands, etc., are used for debugging the facilities.

Today we first introduce this, more about the technical problems of wire bending machine, please pay attention to our subsequent updates.

Please indicate the source of Reprint: belan automation equipment Co., Ltd.

+86-18098256570

+86-18098256570  Email

Email