First, let's introduce how to select equipment according to the needs of their own products:

1. Simple wire forming products can be selected: flat wire bending machine, swivel wire bending machine, special-shaped wire bending machine (camless wire forming machine). Then select according to the product line diameter; General tablet machine, suitable for the production of long products below 7.0mm; Non convex machine is suitable for products with high difficulty in bending short parts below 4.0mm; For products with large wire diameter, head turning machine can better ensure stability. Belan swivel wire bending machine bl-3d-5700 & 8.0mm has high production precision and good stability, but the price is more than half of the foreign price, and the cost performance is very high.

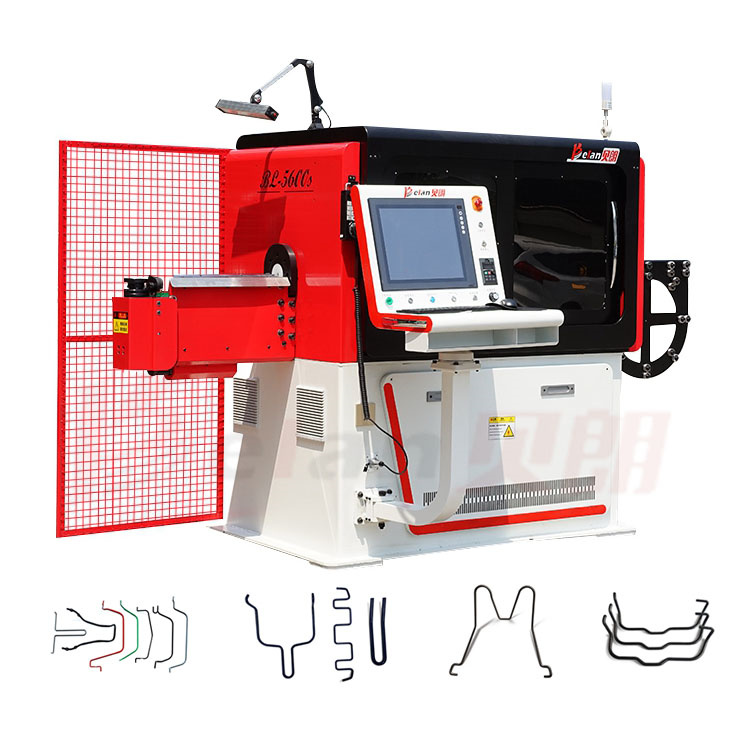

2. For special-shaped and difficult products, choose camless wire forming machine, because it is a fully servo numerical control equipment. There are 8-10 servo motors on the panel, with a relatively high degree of automation, which is very suitable for the production of some small products and special-shaped and difficult products. Making springs is the basic function of, and making special-shaped wire forming also has its obvious advantage of automation.

+86-18098256570

+86-18098256570  Email

Email