1. Bending function

The core function of a copper bar bending machine is to accurately bend copper bars. It can complete bending operations of various shapes according to the set angle, bending radius, and size. The common bending angle range is 0 ° to 180 °, and even complex multi angle bending can be performed.

2. Numerical control accuracy

Modern copper bar bending machines are usually equipped with CNC systems, which can be operated through programming automation to ensure the accuracy and consistency of each bending. This CNC operation greatly reduces human error and improves production efficiency.

3. Hydraulic drive

Most copper bar bending machines are driven by hydraulic systems, providing strong pressure to accurately bend thick copper bars. The stability and controllability of the hydraulic system make it suitable for copper bars of various hardness and thickness.

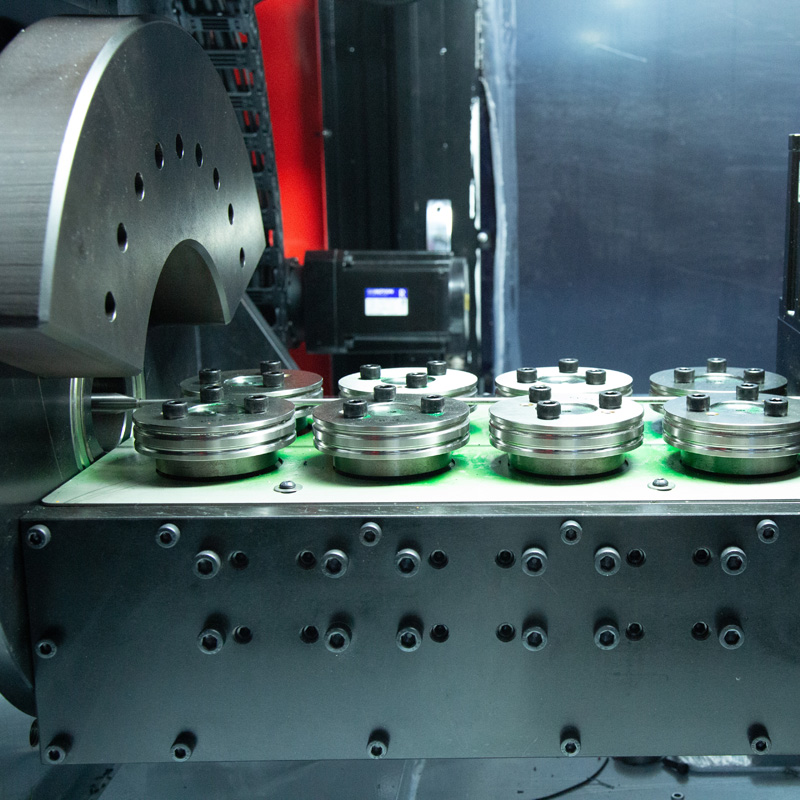

4. Automated clamping and positioning

Copper bar bending machines are generally equipped with automatic clamping devices to firmly fix copper bars and ensure stable position during processing. The automatic positioning function also helps to quickly complete multiple processing without the need for frequent manual adjustments.

5. Multi functional integration

In addition to bending, some copper bar bending machines can also integrate other functions such as punching, cutting, embossing, etc. This can complete multiple processes on one device, improving production efficiency and equipment utilization.

6. Material protection

The surface of copper bars is prone to scratches and oxidation. Copper bar bending machines are usually designed with protective devices to prevent damage to the material surface during processing, ensuring the conductivity and aesthetics of the copper bars.

7. Efficient production

Modern copper bar bending machines are easy to operate, especially when equipped with CNC systems. Operators only need to input processing parameters to complete the entire processing process, greatly improving production efficiency and suitable for large-scale production tasks.

8. Safety design

Copper bar bending machines usually have multiple safety protection measures, such as emergency stop devices, protective covers, hand protection sensors, etc., to ensure the safety of operators during use.

9. Maintainability

The structure of copper bar bending machine is relatively simple, easy to maintain, and the replacement and maintenance of hydraulic system, CNC system and other components are also relatively easy. The service life of the equipment is usually longer.

These functions make the copper bar bending machine an indispensable equipment in the fields of power and electronic manufacturing, capable of efficiently and accurately completing the processing tasks of copper bars.

+86-18098256570

+86-18098256570  Email

Email