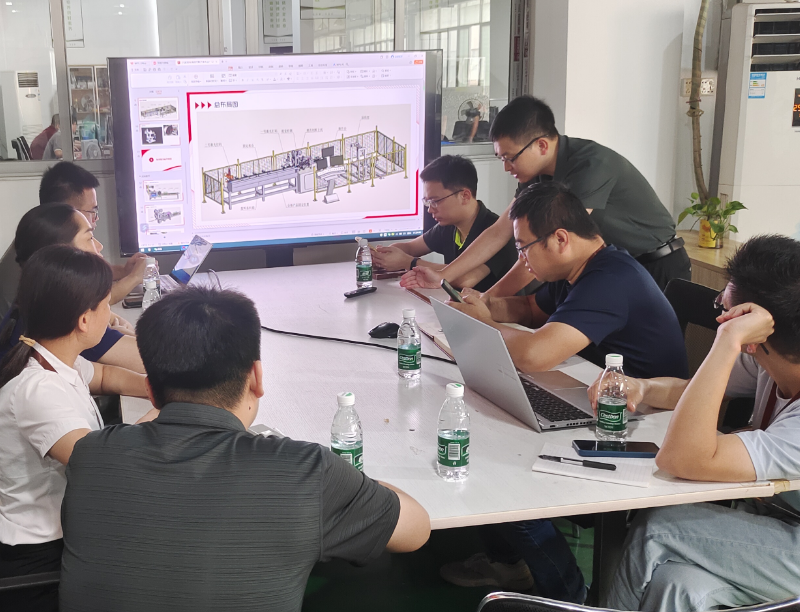

In order to improve the production efficiency and product quality of the aluminum row straightening and bending machine, this improvement meeting was specially held. The purpose of the meeting is to analyze the current operating status of the equipment, identify existing problems, and propose practical improvement plans.

2. Meeting time and place

Time: September 25, 2024

Location: Production Department Conference Room

3. Participants

Head of Production Department

Equipment maintenance personnel

Process engineer

Quality Control Department Representative

Relevant technical support personnel

4. Meeting Agenda

1. Analysis of current operating conditions of aluminum row straightening and bending machines

2. Existing problems and their causes

3. Discussion of improvement plans

4. Determine follow-up measures

5. Analysis of current equipment operating status

Aluminum row straightening and bending machine operation rate: 70%

Product qualification rate: 85%

Mean time to failure: 3 hours/week

Production efficiency: output per hour decreases by approximately 15%

6. Existing problems and their causes

1. Equipment aging: Some key components are severely worn, leading to frequent failures.

2. Improper operation: Some operators are not proficient in using the equipment, resulting in incorrect operation.

3. Unstable process parameters: The bending and straightening process parameters are not standardized, resulting in poor product consistency.

4. Insufficient maintenance: Routine maintenance and upkeep are not in place, and equipment reliability decreases.

7. Improvement plan

Equipment upgrade: Replace critical components that are severely worn.

Consider introducing new technologies and equipment to improve automation levels.

Operation training:

Regularly organize equipment operation training to improve operator skills.

Establish an operation manual and clarify operating specifications.

Standardized process parameters:

Evaluate current processes and develop standardized process parameters.

Establish a process parameter database to facilitate subsequent inquiries and adjustments.

Strengthen maintenance management:

Develop a detailed equipment maintenance plan to ensure daily maintenance of equipment.

Conduct regular equipment inspections and troubleshooting to resolve problems in a timely manner.

8. Follow-up measures

Convene weekly follow-up meetings to evaluate improvement results.

Assign a dedicated person to be responsible for the implementation and supervision of each improvement measure.

Establish a feedback mechanism to collect opinions from operators and technicians for continuous improvement.

9. Summary

Through an in-depth analysis of the aluminum row straightening and bending machines, this meeting clarified the existing problems and proposed corresponding improvement plans. It is hoped that all departments can actively cooperate to ensure the implementation of measures and improve the overall performance of equipment and product quality.

+86-18098256570

+86-18098256570  Email

Email