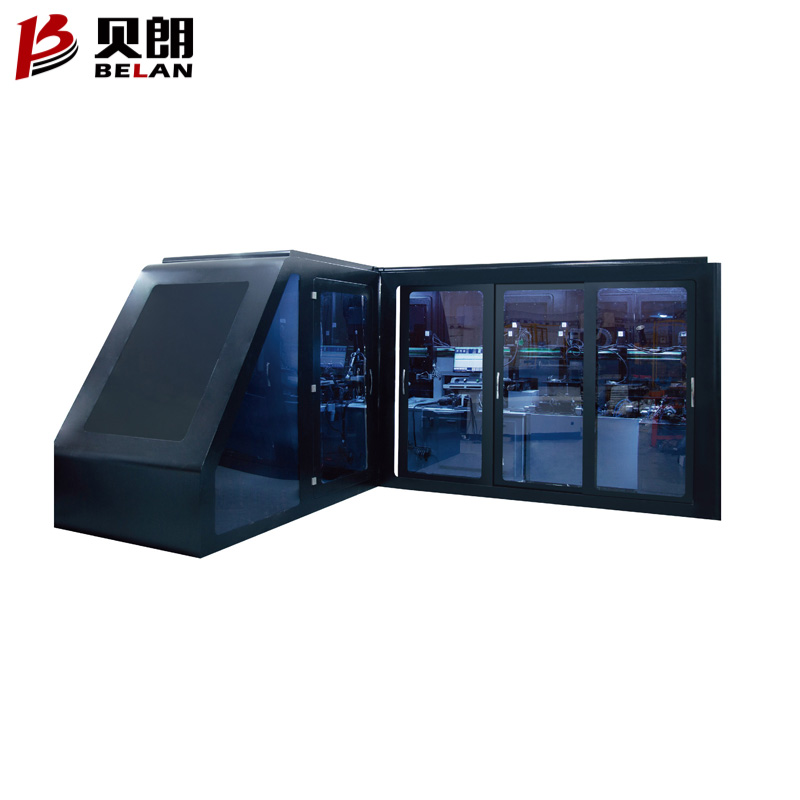

Product Description

Technical Parameters

| Type | Grid machine Parameter |

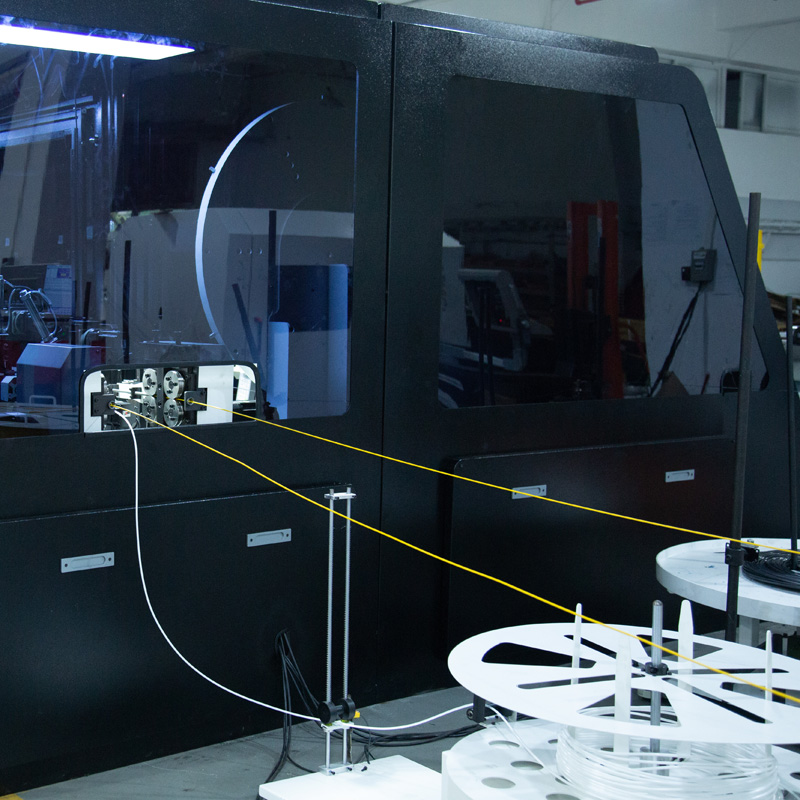

| Applicable Wire Dia. | W-shaped steel wire:Φ2.0mm Plastic wrapped steel wire:Φ3.0mm |

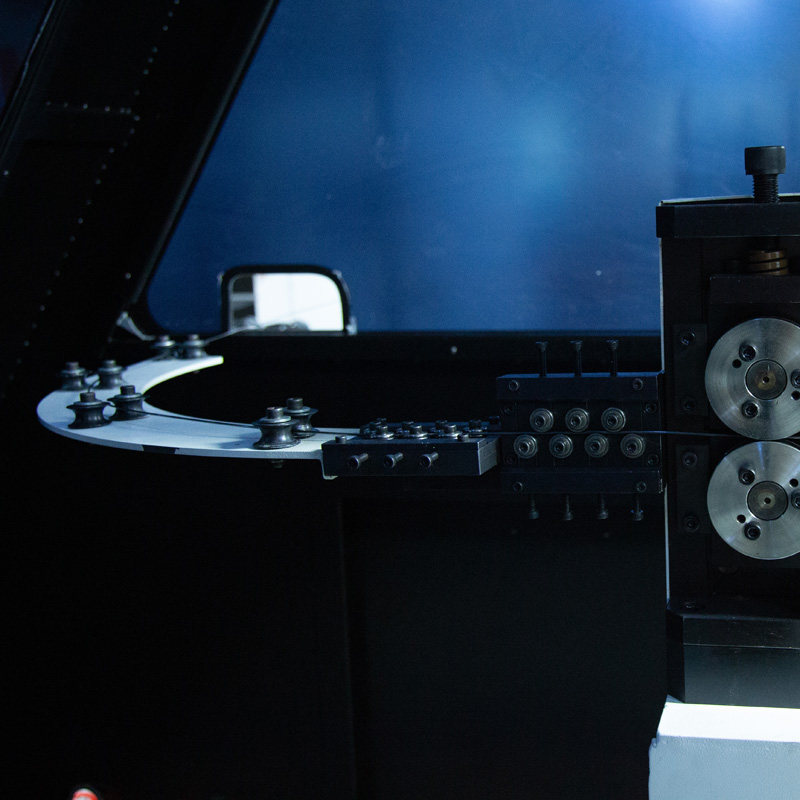

| Number of control Axis | 28-34Axis |

| Total power | 30KW |

| Weaving station | 10 Axis |

| W Forming Station | 2-4Axis |

| Plastic wrapped steel wire station | 12 Axis |

| Sheep Horn Hook Forming Station 1 | 2-4Axis |

| Sheep Horn Hook Forming Station 2 | 2-4Axis |

| Rough stock of process data | ≥2000 |

| Stabilized power (reference) | 40kw |

| Pneumatic system | 0.5-0.6MPa |

| probe | 4 pc |

| Input Power | 380V/50Hz/3Ph |

| Weight | 6000KG |

| Machine Size(L*W*H) | 11500*4500*2400mm |

Product Advantages

Feature and Function

1.Adopting a computer control system, controlled through multi-channel bus.

2. the equipment is formed through servo and pneumatic multi-station bending, and a single station can simultaneously bend multiple angles

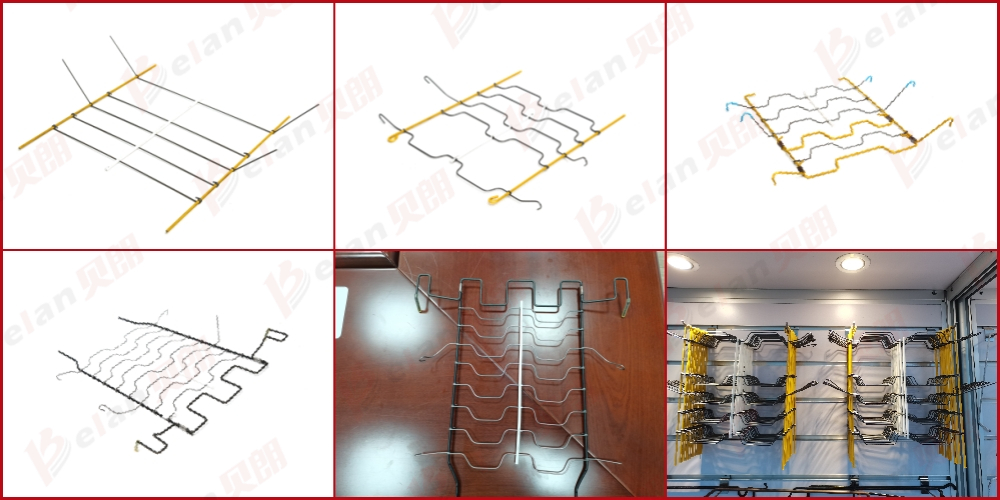

3 it can simultaneously bend and shape steel wire, plastic wrapped steel wire, and weave into a grid.

4.Different conventional grid products can be fully automated by switching molds.

5. Modules can be flexibly customized according to different products of customers.

Wire Bending Machiner Video

Wire Bending Drawing

Manufacturing Capacity

Belang automation equipment co., LTD. is an innovative technology enterprise integrating r&d, manufacturing, sales and system integration services. Focusing on providing customers with solutions for high-precision 3D wire forming equipment, we are committed to promoting the transformation and upgrading of China's manufacturing industry to intelligent manufacturing.

Honor Certification

Customer case

English

English Español

Español

+86-15019083349

+86-15019083349

E-mail

E-mail