Product Description

Technical Parameters

| Type | BL-3D-8300 Parameter | |

| Processing wire diameter | Enameled material: ∮1.0mm-∮4.0mm | |

| Number of wire feed rollers | 2 teams | |

| Turntable angle | ±150° | |

| arm stroke | 70mm | |

| left and right movement range | Left 25mm Right 25mm | |

| wire length | unlimited | |

| 1 axis arm | Sanyo 0.75KW | |

| 2 axis arm | Sanyo 0.75KW | |

| 3-axis arm | Sanyo 0.75KW | |

| 4 axis arm | Sanyo 0.75KW | |

| 5 axis left and right hand | Sanyo 0.4KW | |

| 6-axis curl | Sanyo 0.4KW | |

| 7-axis wire feed | Sanyo 2.7KW | |

| 8 axis turntable | Ou Rui 3.8KW (with brake) | |

| 9-axis peeling machine | Delta 0.75KW (independent control, with vacuum) | |

| Servo total power (KW) | 11.05KW | |

| Maximum wire feeding speed: (m/min) | 80 meters | |

| Feeding accuracy: (mm) | 0.1± | |

| Number of supported programs | 10000 | |

| interface language | Chinese/English | |

| Access voltage | 380V | |

| Machine operating voltage | 220V | |

| Automatic wire feeder motor power: (kW) | 400W | |

| Capacitance (KVA) | 10 KVA | |

| Machine weight: (kg) | 1050KG | |

| Machine size: (L*W*H) (m) | 1846*1841*1727 | |

| Maximum load-bearing capacity of automatic wire feeder: (kg) | 100KG | |

| Maximum diameter of round disc: (m) | Suitable for tray range 200-600mm | |

| Automatic wire feeder size: (L*W*H) (m) | 924*602*1482 | |

| Number of straightening wheels | 14 | |

| Screw guide | 8 | |

Product Advantages

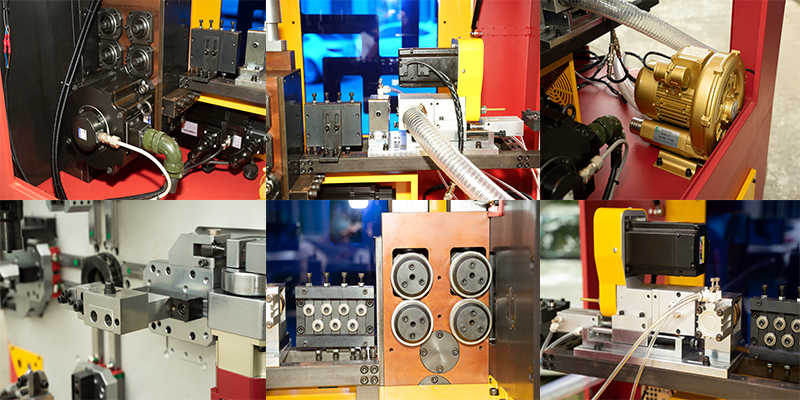

Fully automatic numerical control system

The debugging operation is simple, easy to learn and understand

High precision wire feeding box

High precision - body type wire feeding box, fast, accurate, stable and durable wire feeding

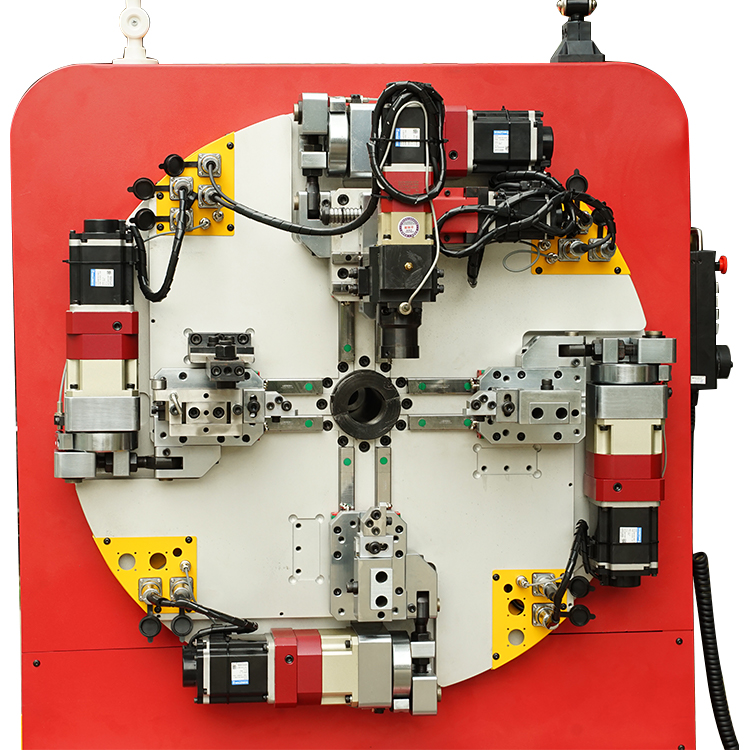

Forming area

Rotatable forming area, four lifting bending arms can be bent, rotated and debugged at will

Straightening wheel

The straightening adopts the form of roller extrusion to straighten the wire without indentation on the surface

Peeling device

Servo motor is used to control alloy turning to ensure the accuracy and consistency of peeling

Peeling and cutting device

During the peeling process, the turning waste can be removed immediately to prevent sundries from entering the confidential Department of the machine

Wire Bender Videos

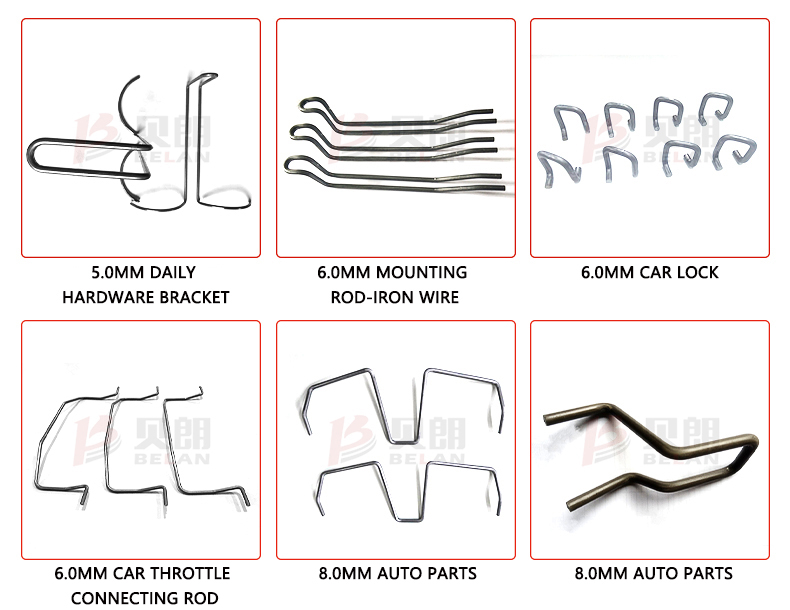

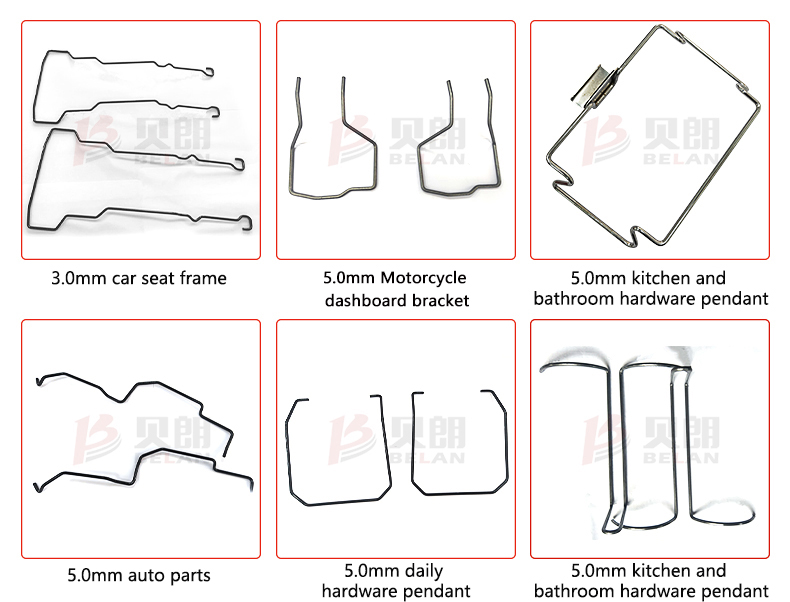

Product Application

Products Are mainly Used In Automobiles, Kitchenware, Garden Tools, Supermarket Shelves, Furniture, etc.

Wire Forming Drawing

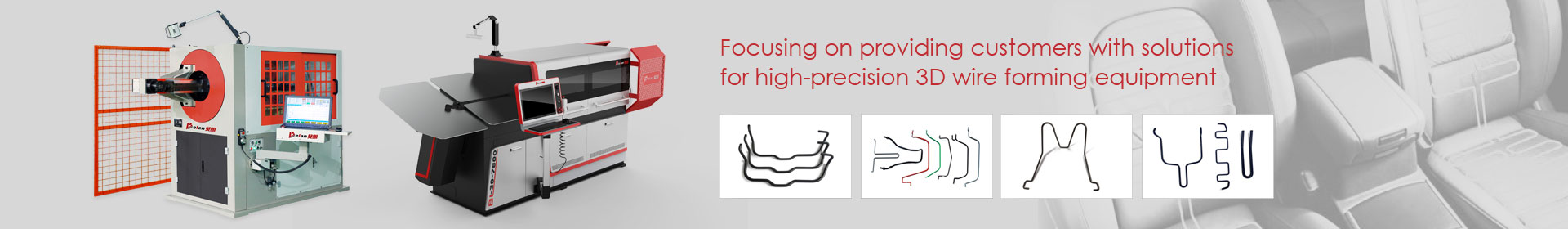

Manufacturing Capacity

Belang automation equipment co., LTD. is an innovative technology enterprise integrating r&d, manufacturing, sales and system integration services. Focusing on providing customers with solutions for high-precision 3D wire forming equipment, we are committed to promoting the transformation and upgrading of China's manufacturing industry to intelligent manufacturing.

Honor Certification

Customer case

English

English Español

Español

+86-15019083349

+86-15019083349

E-mail

E-mail